1

/

of

14

Shipped from abroad _ Delivery in 7 days

1-5pcs 10CC UV Curing Solder Mask Ink Resistance Paste Green Oil for PCB BGA Circuit Board Protect Paint Electronic Repair Tools

1-5pcs 10CC UV Curing Solder Mask Ink Resistance Paste Green Oil for PCB BGA Circuit Board Protect Paint Electronic Repair Tools

Regular price

KSh2,225

Regular price

KSh2,384

Sale price

KSh2,225

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

SPECIFICATIONS

Brand Name: NoEnName_Null

Certification: CE

Choice: yes

Hign-concerned Chemical: None

Origin: Mainland China

Model |

10ML UV Solder Mask Ink |

Material |

Acrylic oligomer |

Dielectric Strength |

>500V/mil |

Solvent Resistance |

Trichloroethane boiled for 2 minutes without falling off |

Solder Resistance |

255-265℃ 10s * 3 times |

Hardness |

>5H |

Curing Condition |

UV light |

Capacity |

10cc |

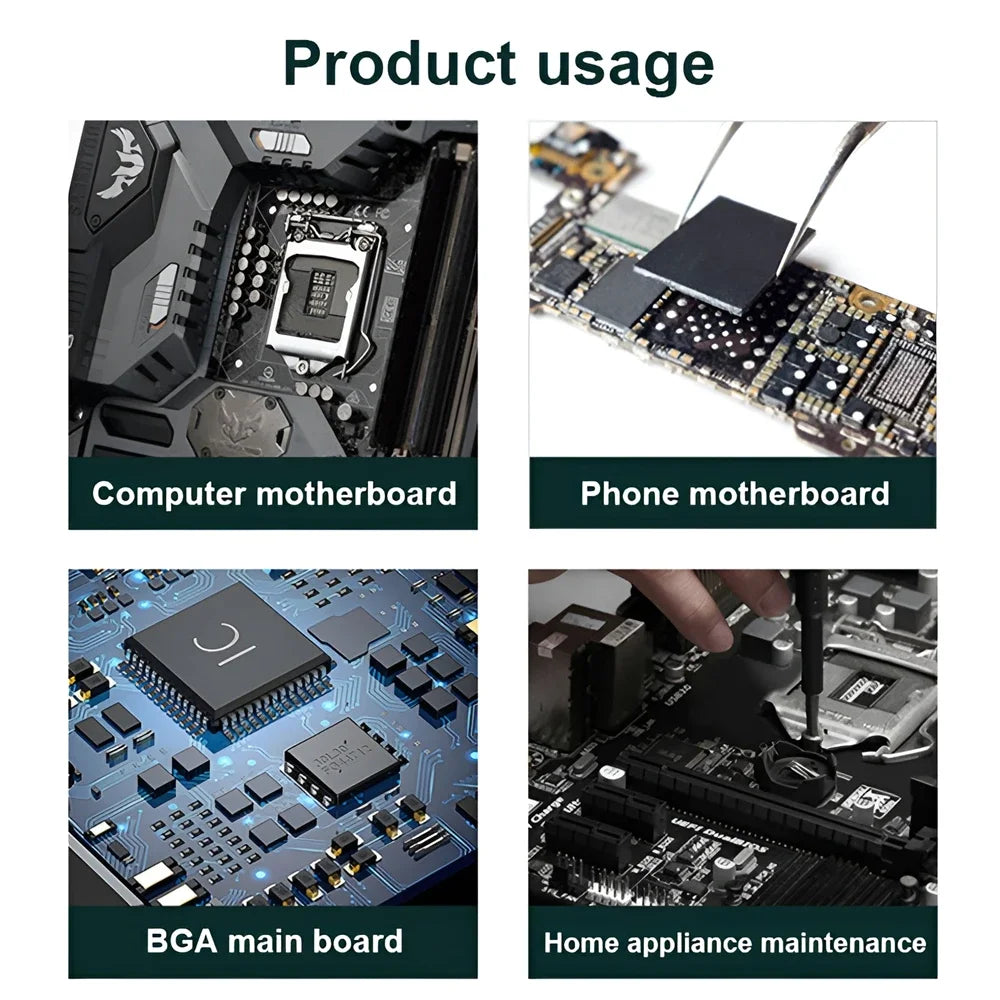

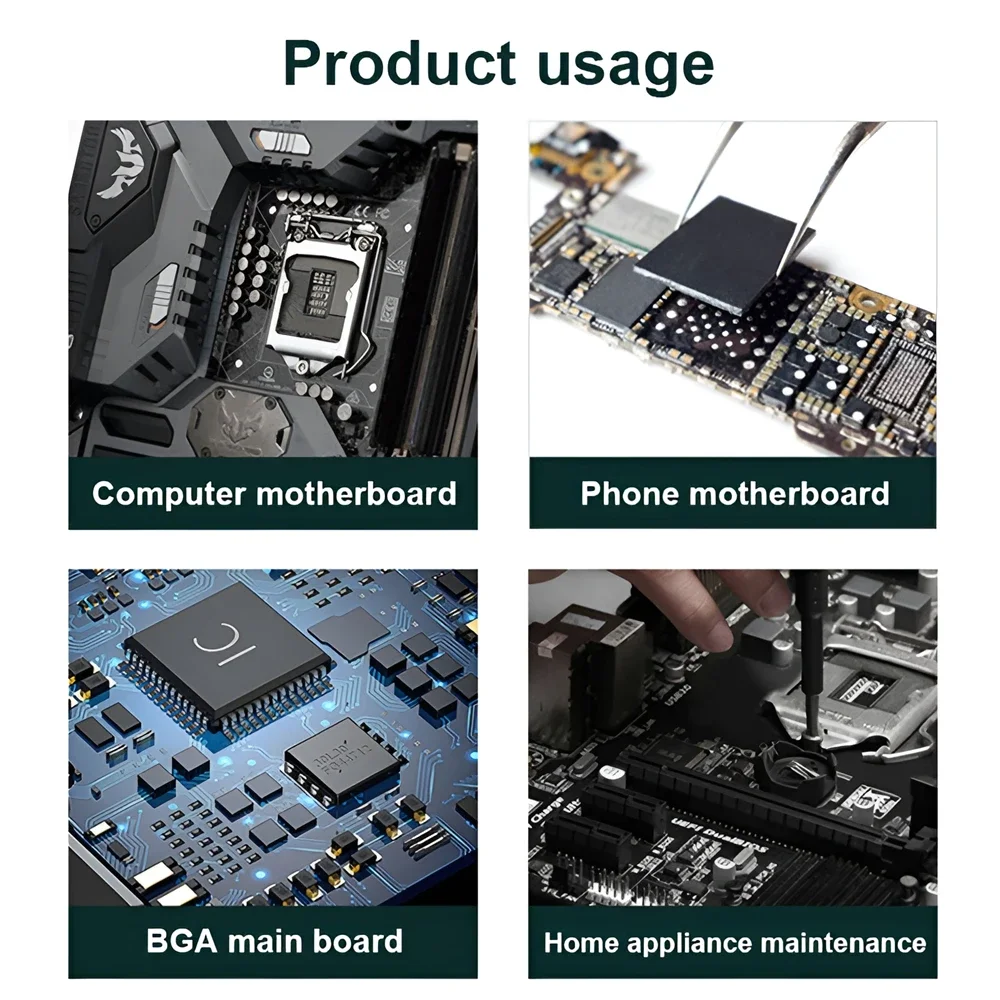

Application |

PCB board repair |

Gross Weight |

About 25g / 1 pc |

Feature:

This is a liquid photo solder resist, is an acrylic oligomer.

Due to the special nature of the material, the solder mask oil will not dry naturally. UV curing is required.

As a protective layer, it is applied to the circuit and substrate on which the printed circuit board does not need to be soldered or used as a solder resist.

The purpose is to protect the formed line pattern for a long time.

Industrial Applications:

Prevent physical disconnection of the conductor circuit.

In the welding process, the short circuit caused by the bridge is prevented.

Welding only in the parts that must be welded to avoid solder waste.

Reduce copper contamination of the welding trough.

Prevent deterioration and corrosion of insulation due to external environmental factors such as dust and moisture.

It has high insulation and makes it possible to increase the density of the circuit.

Instructions:

Apply the soldering mask oil ink to the motherboard that needs to be repaired. (Please apply as evenly as possible, and make sure the coating is not too thick.)

Use the UV flashlight to be curing the coating. (Since the power of the flashlight is relatively small, the curing time is about 5-15 minutes.)

To wipe the wrong substrate, it is recommended to use industrial alcohol or industrial cleaner.

Precautions:

Use only with adequate ventilation.

The solder paste contains organic solvent. Avoid repeated contact with skin. If the solder paste gets on your skin, wipe it off with alcohol and rinse thoroughly with water.

In order to be cautious, in the operation, the smoke released by the solvent during operation should be avoided as much as possible, and the skin and mucous membrane tissues should not be contacted for too long. Avoid repeated breathing of vapor.

Avoid contacting with eyes.

Keep away from children.

Attention:

The measurement allowed error is ±2.0cm.

Light shooting and different displays may cause the color of the item in the picture a little different from the real thing.

In order to prevent counterfeit and shoddy products, we will upgrade the product packaging from time to time, but this does not affect the use, and the old and new packaging will be shipped randomly.

This is a liquid photo solder resist, is an acrylic oligomer.

Due to the special nature of the material, the solder mask oil will not dry naturally. UV curing is required.

As a protective layer, it is applied to the circuit and substrate on which the printed circuit board does not need to be soldered or used as a solder resist.

The purpose is to protect the formed line pattern for a long time.

Industrial Applications:

Prevent physical disconnection of the conductor circuit.

In the welding process, the short circuit caused by the bridge is prevented.

Welding only in the parts that must be welded to avoid solder waste.

Reduce copper contamination of the welding trough.

Prevent deterioration and corrosion of insulation due to external environmental factors such as dust and moisture.

It has high insulation and makes it possible to increase the density of the circuit.

Instructions:

Apply the soldering mask oil ink to the motherboard that needs to be repaired. (Please apply as evenly as possible, and make sure the coating is not too thick.)

Use the UV flashlight to be curing the coating. (Since the power of the flashlight is relatively small, the curing time is about 5-15 minutes.)

To wipe the wrong substrate, it is recommended to use industrial alcohol or industrial cleaner.

Precautions:

Use only with adequate ventilation.

The solder paste contains organic solvent. Avoid repeated contact with skin. If the solder paste gets on your skin, wipe it off with alcohol and rinse thoroughly with water.

In order to be cautious, in the operation, the smoke released by the solvent during operation should be avoided as much as possible, and the skin and mucous membrane tissues should not be contacted for too long. Avoid repeated breathing of vapor.

Avoid contacting with eyes.

Keep away from children.

Attention:

The measurement allowed error is ±2.0cm.

Light shooting and different displays may cause the color of the item in the picture a little different from the real thing.

In order to prevent counterfeit and shoddy products, we will upgrade the product packaging from time to time, but this does not affect the use, and the old and new packaging will be shipped randomly.

Share

No reviews